Tank Filling Level Meter

Introduction

Filling level sensors are crucial for reliably monitoring the contents of tanks and containers, whether liquids, powders, or bulk solids. They play a key role in ensuring process efficiency, preventing overfilling or shortages, and enabling automated control in industries such as manufacturing, food and beverage, water treatment, and logistics.

Among the various technologies available - such as ultrasonic, capacitive, and optical - radar sensors offer the highest precision, reliability, and versatility. Immune to dust, vapors, and temperature fluctuations, radar is the optimal choice for demanding industrial environments and ensures accurate measurements even under challenging conditions.

Beam Pattern Requirements

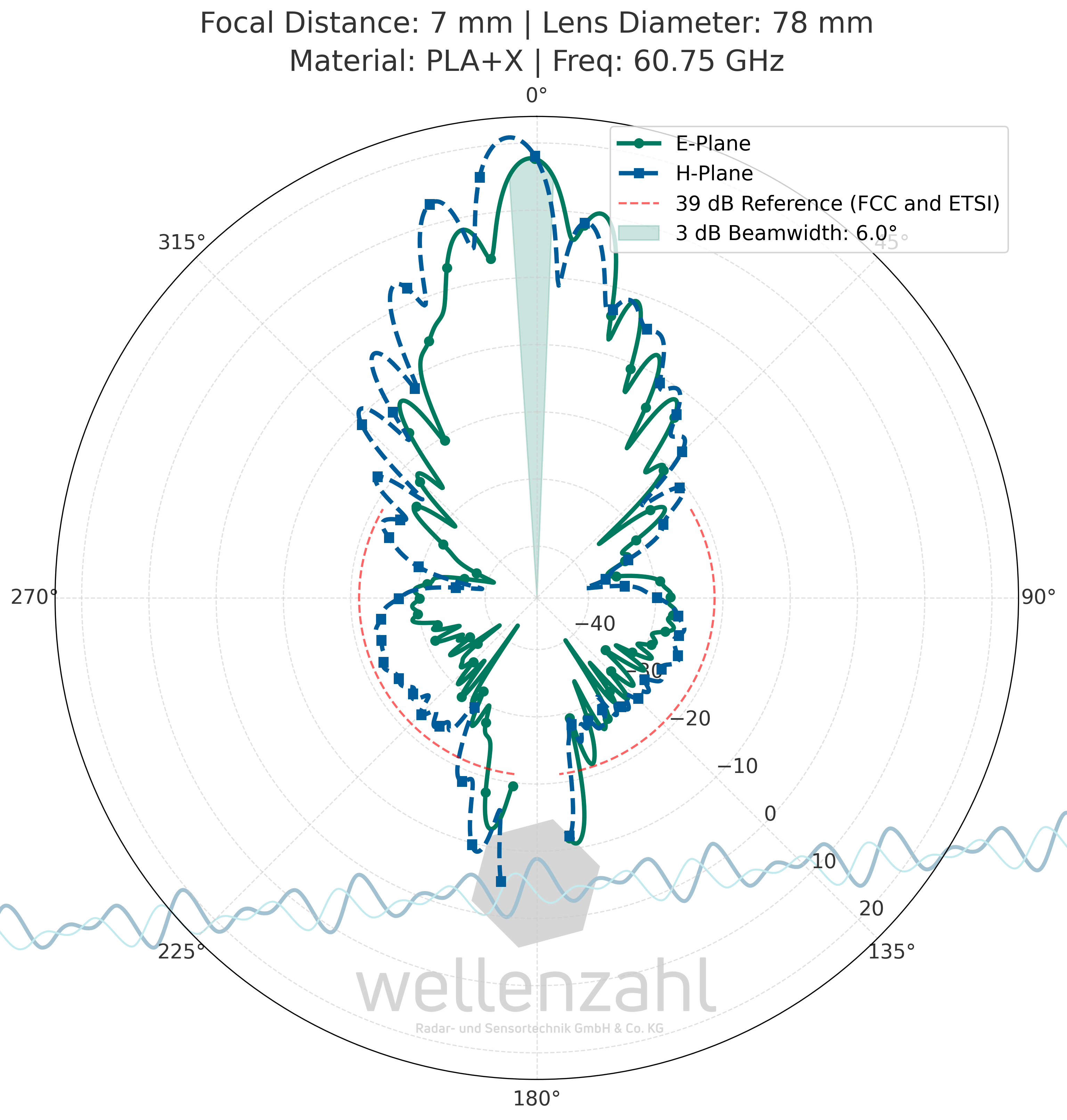

FCC 15.255 and ETSI EN 302.372

The tank filling level meter needs to fulfill the regulations which are defined mainly in FCC 15.255 and ETSI EN 302.372:

- 8 degree half power beam width

- using potting around RF components required in ATEX environments

Besides offering complete custom developments in those areas according to customer specifications, Wellenzahl has developed their own solution with many new upcoming technologies involved.

Custom Solutions

The investigations during development where mainly driven by:

- Selection of radar frontend

- Selection of primary radiator (AoP, PCB, etc.)

- Housing requirements

- Mounting mechanism

- Beam focusing by e.g. lens or horn

A custom development generally required:

- Selection of materials for e.g. housing, lens and horn

- Mechanic and electromagnetic co-design

- Prototype manufacturing

- Prototype beam pattern measurements (in-house)

- Adjusting algorithms to specific application

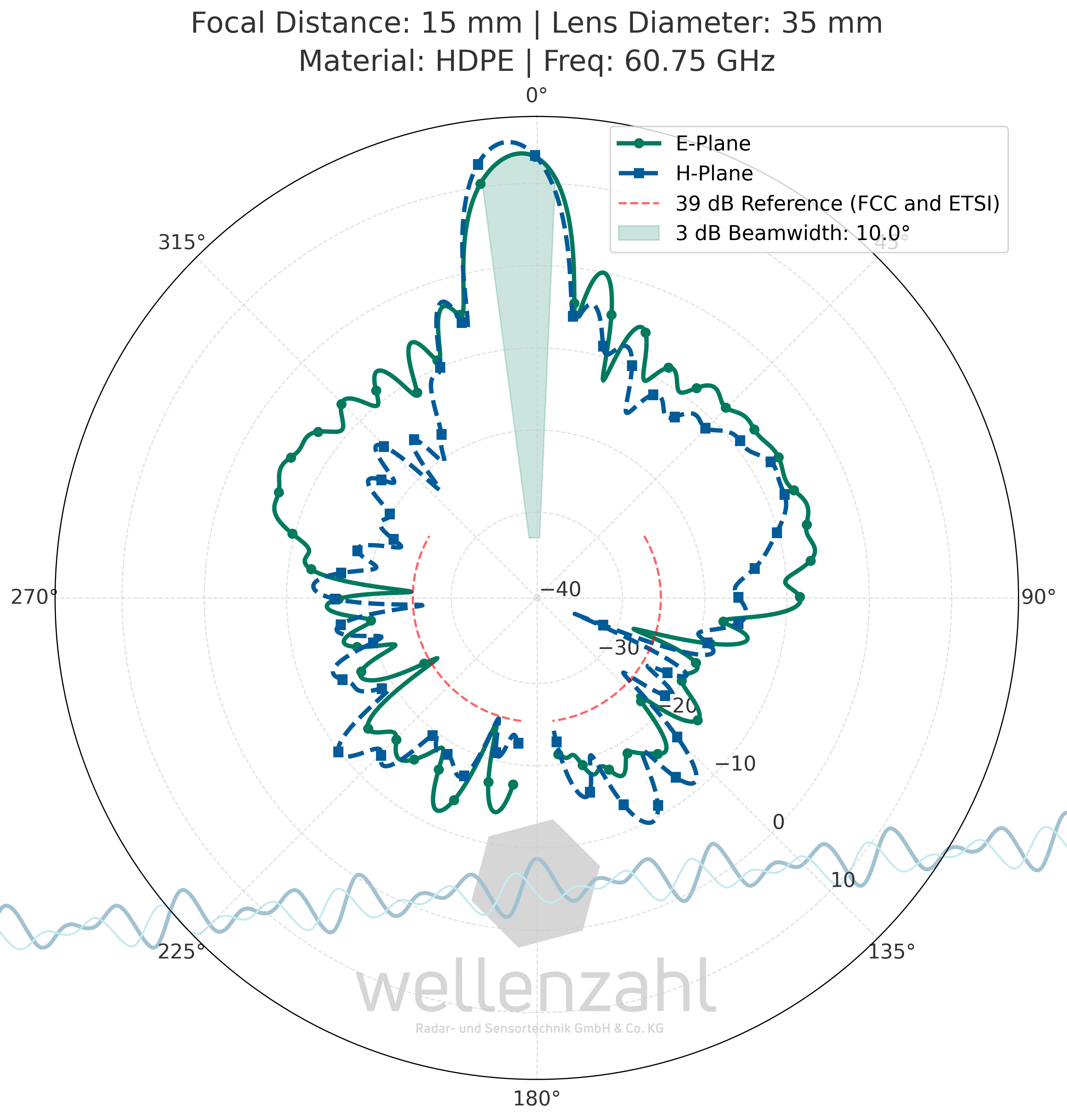

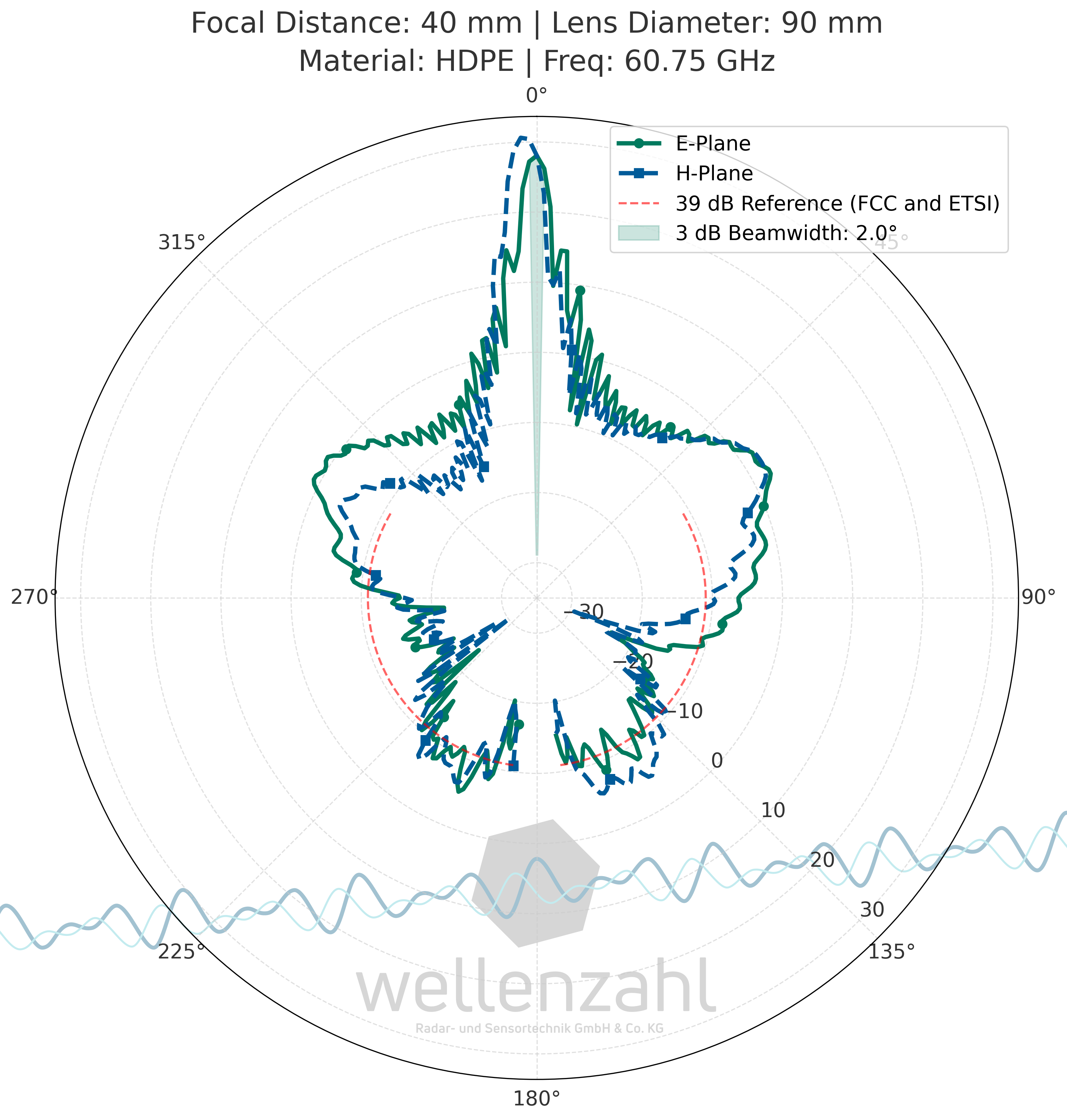

A graph with several technology options is listed here.

Beam Pattern Examples

All Lenses are used on an AoP Radar Frontend

RAPIDv3 and RIot Platform Combinations

Select your readiness level

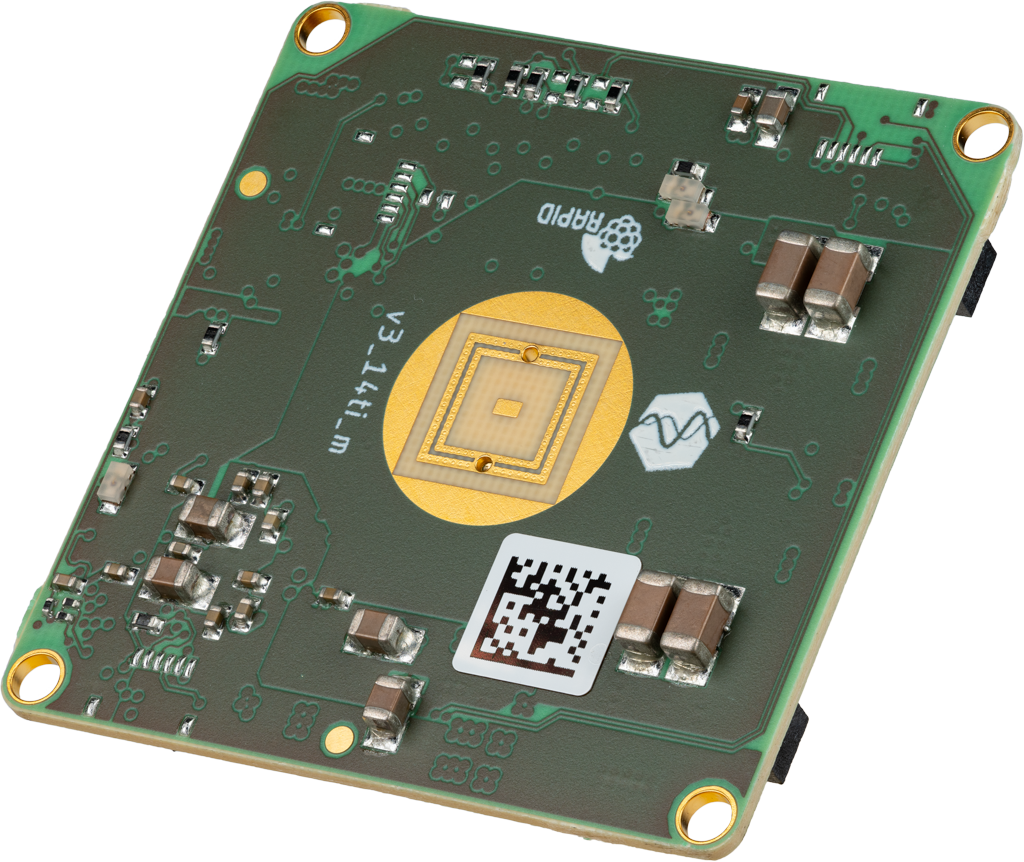

RAPIDv3.2x

Radar Module

Included Hardware:

- Based on IWR1443, IWRL1432, BGT60TR13C or IWRL6432AOP (upcoming)

- AoP antenna architecture

- RAPIDv3 connector as hardware interface

- 34 x 34 mm²

Included Firmware

- Algorithms incl. Wellenzahl's static and dynamic background estimator, ideal for level meters

- Target list incl. magnitude values via UART MODBUS protocol

- Raw ADC data or spectrum via UART MODBUS protocol

Additional requirements for FCC 15.255 and ETSI EN 302.372

- dielectric lens

- housing which meets mechanical and electromagnetic requirements

- technologies like CNC machining, injection molding, metallized plastics

Wellenzahl offers:

- Designing of lens and housing according to customer specification

- In-house beam pattern measurements

- supporting FCC and ETSI test procedure

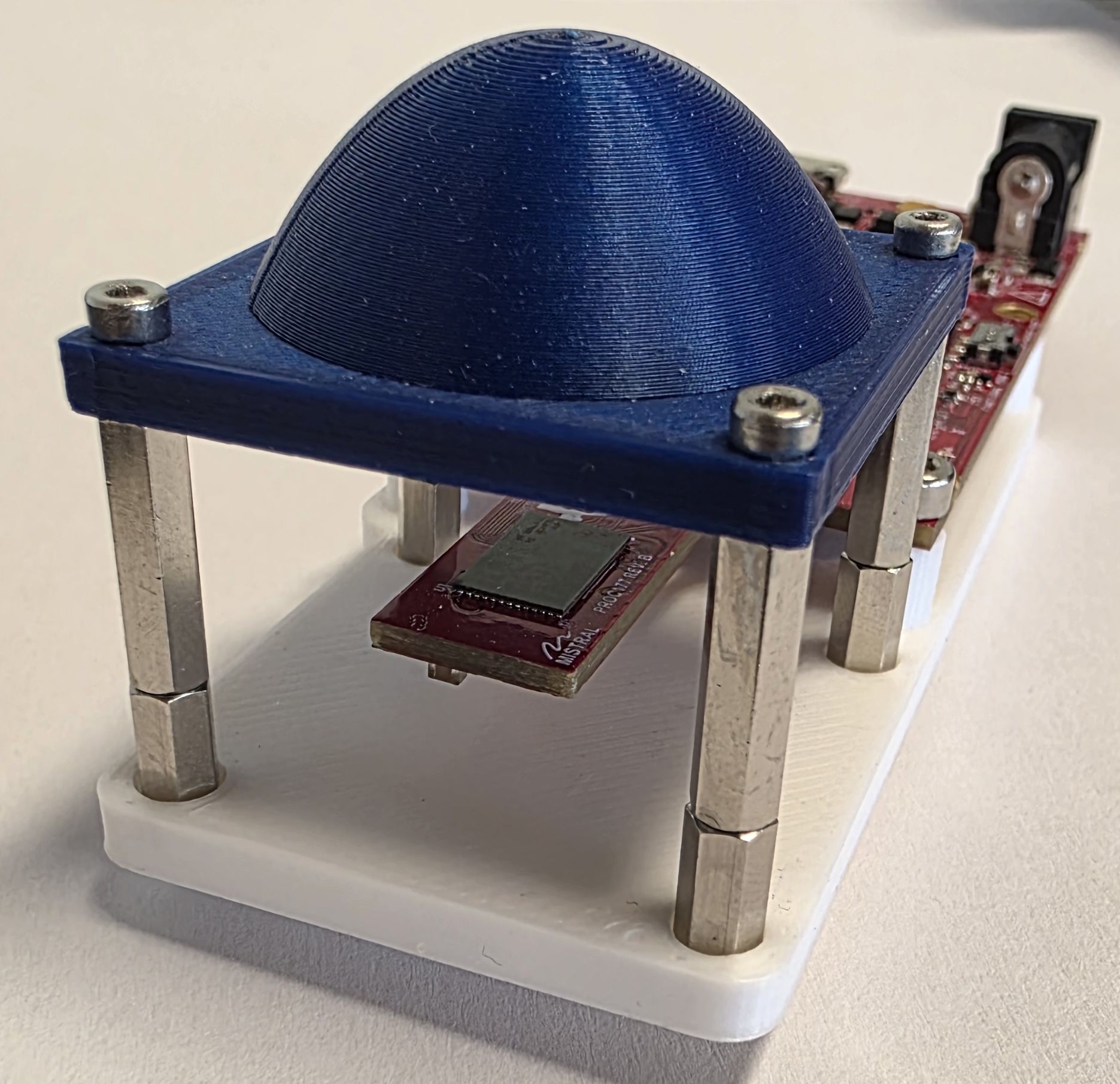

RAPIDv3.2x + Dielectric Lens

Radar Module + Beam Focussing

Included Hardware:

- Based on IWR1443, IWRL1432, BGT60TR13C or IWRL6432AOP (upcoming)

- AoP antenna architecture

- RAPIDv3 connector as hardware interface

- 37 x 37 x 75 mm³

Included Firmware

- Algorithms incl. Wellenzahl's static and dynamic background estimator, ideal for level meters

- Target list incl. magnitude values via UART MODBUS protocol

- Raw ADC data or spectrum via UART MODBUS protocol

Additional requirements for FCC 15.255 and ETSI EN 302.372

- housing which meets mechanical and electromagnetic requirements

- technologies like CNC machining, injection molding, metallized plastics

Wellenzahl offers:

- Designing housing according to customer specification

- In-house beam pattern measurements

- supporting FCC and ETSI test procedure